High pressure valves up to 15,000 psi in the field of measurement and control

We all know, pressure is one of the most important process parameters, in the field of measurement and control.

Pressure measurement under extreme applications are done for enormously high-pressure range.

These measurements must be safe and precise, for which we need reliable valves to maintain tight control and regulation at these high pressures.

It is this crucial combination of High Pressure + Safety + Accuracy + Reliability + Durability that sets the preface of my article. AS-Schneider’s powerful “high pressure valves up to 15,000 psi”.

If we speak of high pressure applications, it is mainly existent in critical part of Oil & Gas, Chemical, Petrochemicals and Power.

In such applications, operating conditions with extreme pressures must be vigilantly monitored by the operator to prevent failures, safety hazards and decreased production.

For example, emerging oil and gas recovery techniques used in deep-sea offshore and enhanced oil recovery operations are pushing to ever higher pressures, it is critical that Instrumentation be robust enough to provide accurate measurements on a consistent basis.

I would like to share with you one of our client’s requirement for high pressure valves and our solution.

Application example:

High pressure valves in offshore application

Requirement for high pressure valves

One of our offshore clients, has an application for high pressure measurement using transmitter which requires below valves:

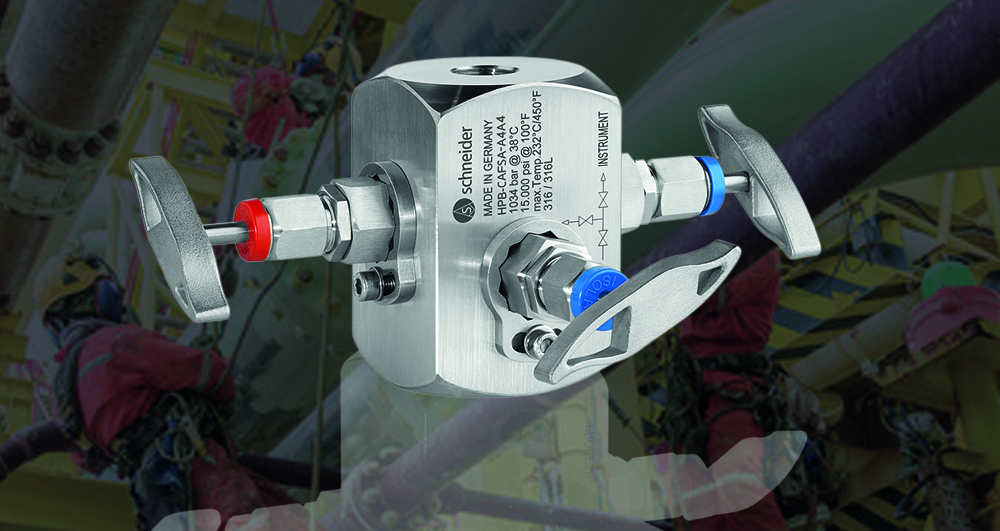

- Pressure measurement with a Block and Bleed type 2-valve manifold of 15,000 psi (1,034 bar), special process connection of 9/16-18 UNF threads, MOC – SS 316L.

- Differential Pressure measurement with a 5-valve manifold of 15,000 psi (1,034 bar), special process connection of 9/16-18 UNF threads, MOC – SS 316L.

Additionally, these valves were supposed to be supplied with MTC 3.1, Pressure tested, 100% PMI for body, NACE MR0175/ISO 15156.

Application solution

Due to the high requirements, it was immediately clear to me that only our high pressure valves (15,000 psi (1,034 bar)) could be considered for this application.

The high pressure valves are designed and tested for superior pressure-performance for all critical applications in the Oil & Gas, Chemical and Petrochemical Industry. The Valves allow leak tight shut-off, for the ultimate control and regulation.

And the metal to metal secondary back seat provides an additional sealing to atmosphere and releases if use the packing. That means, there is less wear on packing which leads to more safety for the user (anti-blowout / non-removable). The high pressure valves also have a special thrust bearing of the stem/valve tip connection to absorb highest stem forces.

Last, we offered the high pressure valves in our standard MOC – 316/316L, tested in-house with PMI.

Recently, I spoke with the customer, the high pressure valves are successfully installed and commissioned at the site. They are performing robustly against the high pressure in the process.

Image Source: © phojaip, FishCoolish, Penti, Sergey (Adobe Stock) & AS-Schneider